熱成形 EVA ケースの製造工程全体は、EVA 材料の準備 → 表面材料の選択 → EVA 切断 → 箱のロゴまたはパターン処理 → 予備プレス → 熱成形 → 冷却とトリミング → ステッチ、検査、梱包の 8 つの段階に分けられ、多用途の EVA 収納ボックスが完成します。

重要なプロセスパラメータは熱成形段階に集中します。

以下では、各ステップを順番に説明し、よく使用される制御範囲も示します。これにより、ブランドはペンケースや EVA 収納ボックスを設計およびカスタマイズする際に直接参照しやすくなります。

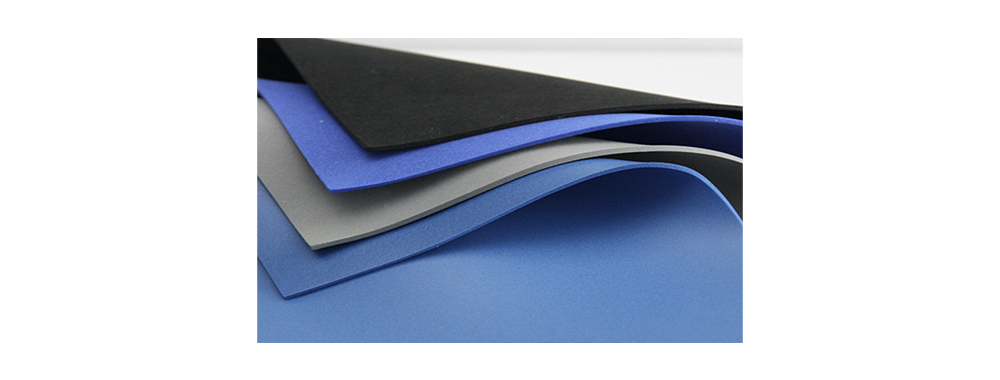

適切な硬度の EVA を選択します。鉛筆箱に必要な壁の厚さと硬さに応じて、密度 200~300 kg/m³、硬度 55~80 度の EVA フォーム シートを選択します。

眼鏡ケースや iPod ケースなどの軽量小型 EVA ケースには、硬度 65 度の EVA が推奨されます。

工具ケースや電子製品の収納ボックスの場合、ケースの形状を維持し、簡単に変形しないようにするために、硬度は 75 度以上が推奨されます。

適切な硬度のEVAシートを選んだら、次はEVAシートにラミネートする表面生地を選びます。最も一般的に使用されるのはポリエステルニット生地です。滑らかな表面と優れた弾力性を備え、比較的低コストであるため、標準的なEVAケースのほとんどで第一選択肢となっています。

さらに、お客様は製品要件やブランドポジショニングに基づいて、カスタマイズされた素材を選択することもできます。例えば、EVAをラミネートしたPUレザーは、ペンケースやEVAオーガナイザーケースなどの製品によく使用されます。

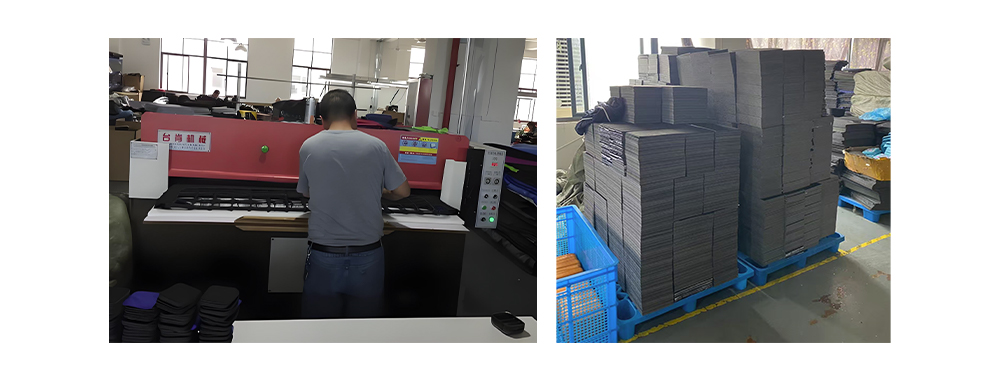

ラミネートEVAシートを平らに置き、個々のピースに切断します。切断サイズは、金型の周囲長より約20mm大きくしてください。この余裕を持たせることで、収縮率の異なる材料が十分に伸びる余地が確保され、熱成形工程中の材料不足を防ぐことができます。

4.1. EVAボックスの装飾パターンやロゴは、シルクスクリーン印刷、熱転写印刷、または昇華印刷で印刷できます。これらの印刷は、後続の熱成形工程の影響を受けません。

4.2. デボス加工によるロゴ:パターンやロゴを熱成形金型に直接デボス加工することで、ワンステップで成形できます。この場合、上記のように追加のロゴ装飾は必要ありません。

まず、材料を 60 ~ 80 °C のオーブンで 30 ~ 60 秒間予熱します。これにより、後続の熱成形サイクルが短縮され、表面の平坦性が向上します。

次に、カットしたシートをコールドプレス金型に置き、2~4MPaの軽い圧力を5~10秒間加えます。これにより、シートが金型に初期的に馴染むため、熱成形時の滑りやずれが軽減され、シワも最小限に抑えられます。

これは熱成形EVAケース製造の中核となる工程です。電気加熱式プラテンと上下金型温度の独立制御を備えた4列熱成形機を用いて、ケースの最終形状が成形されます。

壁厚3mmの場合、約45秒

壁厚4mmの場合、約60秒

EVAの厚さが1mm増えるごとに、熱成形時間を10~15秒増やします。

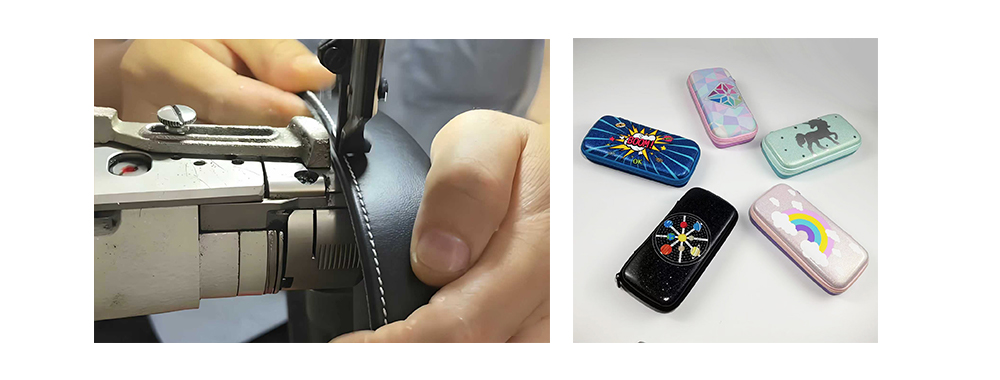

熱成形された EVA カバーまたは底ケースをジッパー テープやウェビング キャリー ハンドルなどの他のコンポーネントと一緒に縫い合わせ、空気圧リベット マシンを使用してリベットやロゴ パッチなどのハードウェアを追加します。これで、1 つのペンケースまたは収納ボックスの組み立てプロセスがほぼ完了します。

最後に、マスターカートンに梱包する前に検査と発券を行います。

温度が 5 °C 上昇するごとに、圧力は 1 MPa 低下し、その逆も同様です。

深いキャビティの金型では、縁の焦げ付きを防ぎ、成形中の表面の泡立ちや積層布の局所的な剥離などの問題を軽減するために、0.05~0.1 mm のベント溝が必要です。

量産前に最適な冷却時間をテストしてください。不要な冷却時間を短縮することで、生産性を大幅に向上させることができます。

雨が続いたり、湿度が高い日には、製造前にシートを約 50 °C で 3 時間ほど予備乾燥させることをお勧めします。

温度、圧力、冷却時間を記録し、異常が見つかった場合は直ちに機械を停止し、金型を調整してください。

上記の手順とパラメータに従うことで、標準的な壁厚 5 mm の EVA ケースでは、1 台あたり 1 日あたり 1,200 個の生産量を 98% 以上の歩留まりで達成できます。

| 著者 | ||||||

|

著作権

@2024 Synberry Bag & Package Products Co.,Ltd 無断転載を禁じます

.

サポートされているネットワーク

サポートされているネットワーク

サイトマップ / ブログ / Xml / プライバシーポリシー